Project Overview

Textile effluent treatment is typically managed with flocculation and aeration, which require heavy chemical use, electricity, and generate large sludge volumes. For dyeing and bleaching units in Perundurai, this leads to high operating costs and environmental concerns.

BEADS™ Technology Solution

Bio-Electrochemical Anaerobic Digestor System (BEADS™) developed by JSP Enviro provides a sustainable alternative:

Recovers Energy

Anaerobic fuel cell-based process that treats wastewater while generating electricity or methane.

No Chemicals & Minimal Sludge.

No chemicals required for treatment. Upto 80% reduction in sludge.

Modular Design

No concrete structure required. Modules can be added as capacity increases.

Pilot Deployment Details

Site

SIPCOT, Perundurai, , Tamil Nadu

Capacity

50 m³/day

Operation Period

6 months

Operation Mode

Continuous and batch-fed with sludge seeding

Integration Process

- Effluent bypassed from equalization tank

- Treated in BEADS™ system

- Returned to ASP for final polishing

Performance Results

6-Month Operational Data & Extended Trials

6-Month Operational Data

COD Reduction

60-65%

BOD Reduction

65-70%

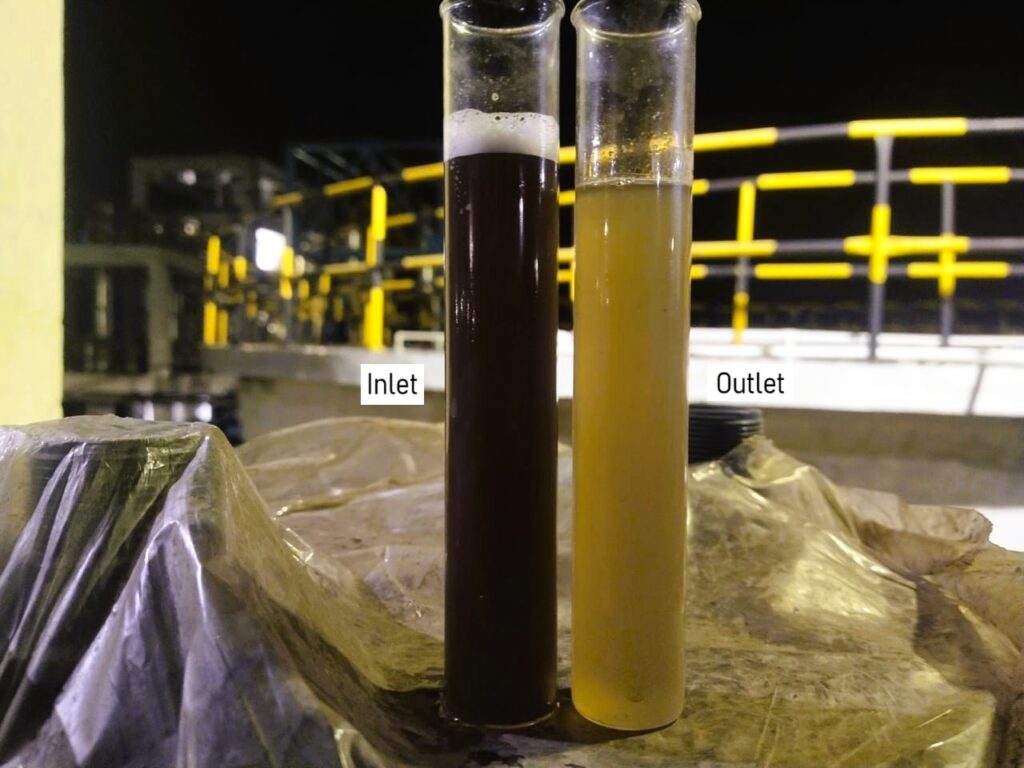

Color Reduction

60-70%

Retention Time

8-10 hours

Energy Usage

0.25-0.5 units/day

Optimum Retention Time

At 100% flow (1000 LPH)

8 hours

COD Reduction

64% avg

BOD Reduction

70% avg

TSS Reduction

42% avg

Color Reduction

65% avg

Process Optimization Insights

Higher COD Load

Improves system performance

MLSS Optimization

6500–8500 ppm (MLVSS/MLSS ≈ 0.6)

Critical Controls

pH (6–7.5), TDS (2000–6000 ppm), MLSS balance

Cost & Environmental Impact

Treatment Cost

₹0.14–₹0.25/m³

Very low OPEX compared to conventional methods

ROI Period

2 - 3 years

For a 300 KLD system

CO₂ Savings

234 tonnes/year

2.6 kg CO₂ saved per m³ treated

Chemical Reduction

PAC, CRP, and sludge dryer operation cut by 60–80%

Key Outcomes

Consistent Performance

COD/BOD reduction of ~60–65% with strong colour removal capabilities

Scalability Potential

BKS Textiles evaluating scale-up to 500 m³/day based on pilot success

Operational Robustness

Low energy use, durable electrodes, and minimal operator intervention required

Sustainability Achieved

Significant reduction in environmental impact with minimal chemical usage and sludge production